At Wantong providing high quality products is our highest priority and in order to ensure the quality of the products, we conduct rigorous inspection of all raw materials and spare parts entering the factory.

Wantong will conduct full inspection, sampling inspection and batch inspection according to industry standards.

Wantong owns 5 professional hydraulic cylinder design engineer, could design products and make to order based on customer requirements. Each one of them has over 10 years working experience, familiar with all types of cylinder design, manufacturing and usage. Wantong also provides training with the newest information on hydraulic cylinder every year.

All metal components are Wantong self-fabricated during the manufacturing of hydraulic cylinders. Each cylinder cap and piston is hydrocarbon cleaned after production to prevent from impurity and rotten. All parts are then sent back to assembling worship, and run through second cleanser after assembling.

We use carbon dioxide shield welding method to make sure the products are well welded, and polish to ensure beauty. After welding, we would check the welding size and quality, appearance, existing of air vents dirt or other problems and final clean and polish.

We use electrostatic powder spraying to make sure the paint on product surface is strong and adhesive. This not only shortens the time of spraying but also improves production efficiency.

- Cylinde: 20# Steel

- Cylinder ca: QT450

- Pisto: QT450

- Piston Ro: 45# Steel, Chromium-plated

- Sealing elements: We use sealing parts on your demand; mostly use sealing parts from ASTON

These parts have been used for years from our experience, but we can always order special material components on your demand.

Each product would run through a 5+ mins operation examination, and also check if any fluid leaking exists. The cylinders passed would be checked again by our quality assurance agent and packed to be delivered worldwide.

In terms of production, Wantong continuously upgrades the production equipment and improves the manufacturing efficiency.

CNC Machining

In regards to our CNC lathe, we have added a CNC machining center and Haas precision CNC machine tool to reduce the tolerance of parts processing and improve the machining accuracy.

Skiving & Roller Burnishing

The CNC skiving and roller burnishing machine is used to process the inner surface of the cylinder to provide smoothness and achieve a mirror effect, while improving the hardness of the cylinder.

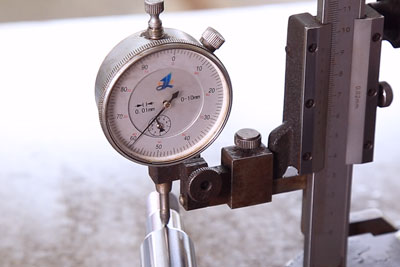

Accuracy Inspection

In addition, we will carry out strict quality and tolerance accuracy inspections of the processed semi-finished products, so that the quality of Wantong´s products is guaranteed.

Welding

The welding used by Wantong is carbon dioxide protection welding, the welding operation is carried out by experienced workers to ensure the smoothness of the weld.

Spray Coating

The surface of the product is sprayed with electrostatic powder, which not only ensures the adhesion and toughness of the surface paint, but also shortens the drying time of the paint and greatly improves the production efficiency.

Cleaning

Before assembly, every cylinder head, piston and other parts will be cleaned with the hydrocarbon cleaning machine, which not only removes impurities from the parts, but also plays a vital role in rust protection. After the assembly is completed, the second cleaning process will be performed.

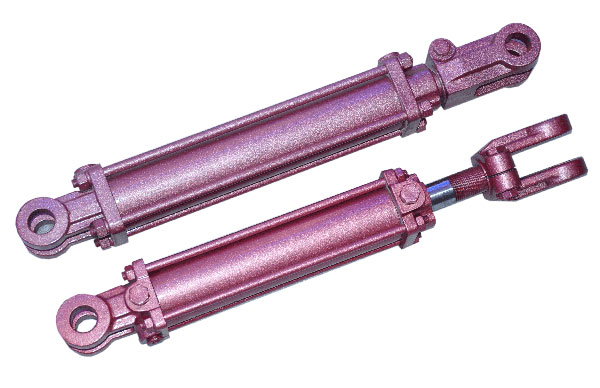

Assembly & Testing

After each product is finished, we will carry out the experimental test of holding pressure for more than 5 minutes and the repeated telescopic detection. At the same time, we will check whether there is oil leakage at the cylinder head and oil port.

Packaging

The cylinders that have passed testing and inspection are then checked for dimensions again according to the drawings. After confirming that there are no problems, we pack and ship the products to customers all over the world.