Hydraulic Cylinder

-

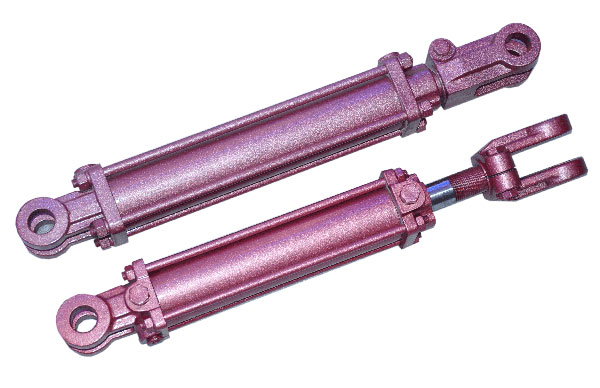

- Welded Hydraulic Cylinder Welded hydraulic cylinders and tie rod hydraulic cylinders are most frequently used on the market. One of the differences between hydraulic welded cylinder and hydraulic tie rod cylinder is that the former has no tie rods, while the latter has.

-

- Tie Rod Hydraulic Cylinder Tie rod hydraulic cylinders, or simply tie rod cylinders are designed with threaded steel rods to fix the two end caps to the cylinder barrel, and the steel rods are always durable and feature high strength. Tie rod hydraulic cylinders are commonly used in industrial factories.

-

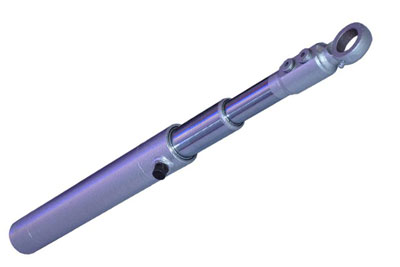

- RAM Hydraulic Cylinder RAM Hydraulic Cylinders are also known as piston type cylinders. They are actuating cylinders in which the cross-sectional area of the piston is less than one half of that of the movable element. RAM Hydraulic Cylinders are the most frequently used type in fluid power systems ..

-

- Telescopic Hydraulic Cylinder The telescopic cylinders use multi-stage rod, made of series of diameter descending chromium-plated steel tubes. Each stage rod needs to achieve a chrome plated layer of 0.03mm to decrease corrosion and increase wear resistance.

Functions and Applications

- A hydraulic cylinder is also called a linear hydraulic motor.

- Hydraulic cylinders find applications in various fields, typically in construction machines and road equipment as well as many other heavy duty vehicles, including excavators, cars, trucks, and more.

- As a mechanical actuator, a hydraulic cylinder functions to produce a unidirectional force by getting power from pressurized hydraulic fluid.

Composition and Working Principle

- The primary parts of a hydraulic cylinder include cylinder barrel, cylinder cap, cylinder head, piston, piston rod, rod gland, and so on.

- In a cylinder barrel, a piston is connected to a piston rod. The piston rod comes out of the cylinder through the cylinder head, and the piston divide the barrel into two separate chambers, the cap end and the rod end. Each chamber is connected to an oil hole. When one of the holes is filled with hydraulic fluid, the fluid pressure will push the piston to move, which drives another oil hole to discharge hydraulic fluid and in the meanwhile, drives the piston rod to move back and forth.

Classifications

A hydraulic cylinder can be divided into several categories, including tie rod cylinders, welded body cylinders, single acting cylinders, double acting cylinders, double acting micro cylinders, telescopic cylinders, piston cylinders, differential cylinders, and rephasing cylinders, to name a few,